Congcong Luo, Minghang Zhao, Song Fu, Yan Zhang, Yan Han, Qingqing Huang, Zhiquan Cui

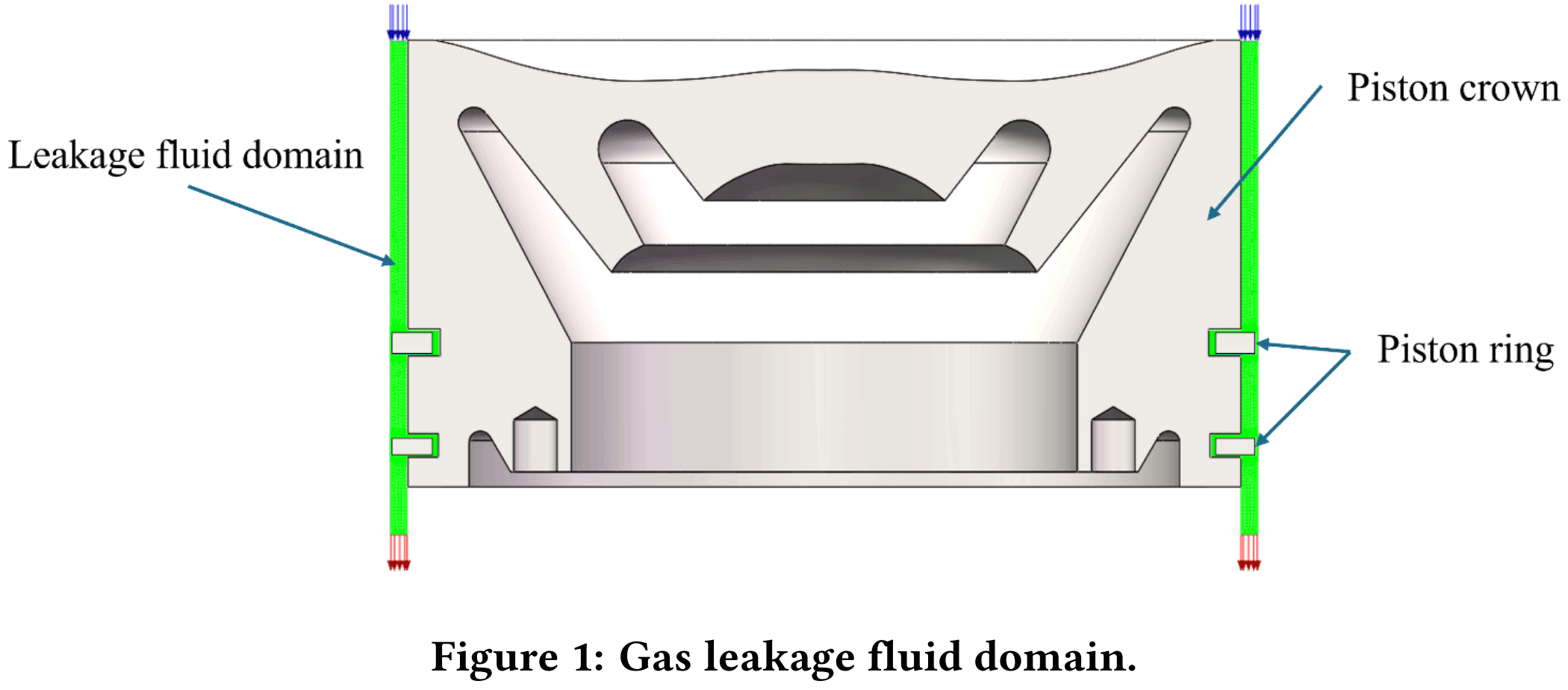

Given the practical challenges and limitations associated with conducting destructive experiments on large marine diesel engines, numerical simulation has emerged as a critical method for elucidating piston ring failure mechanisms and compensating for the scarcity of experimental data. Focusing on the piston ring, piston, and cylinder liner system, this study establishes a coupled model that integrates a 2D fluid domain with a 3D piston ring structure. The solution accounts for multi-physics interactions involving thermal, fluid, and structural factors. Unlike conventional standalone fluid analyses, this model incorporates the temperature- and pressure-dependent viscosity of gases, the k-ϵ turbulence model, and the structural deformation of the piston ring under load into a unified computational framework to simulate the complex physical environment within the cylinder.

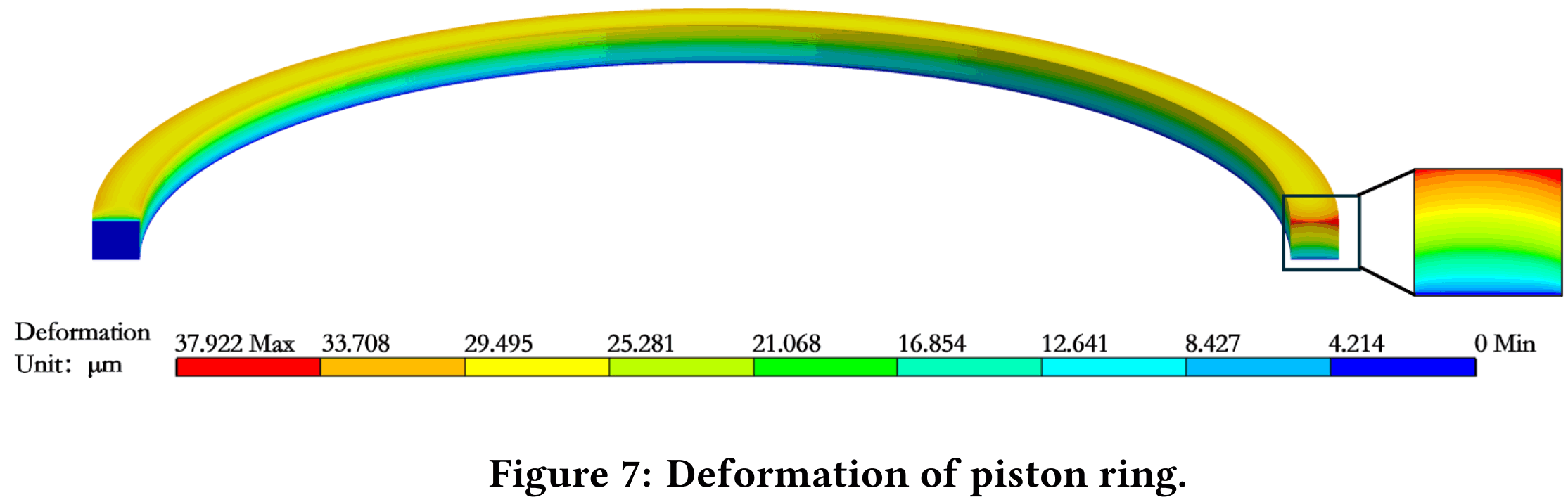

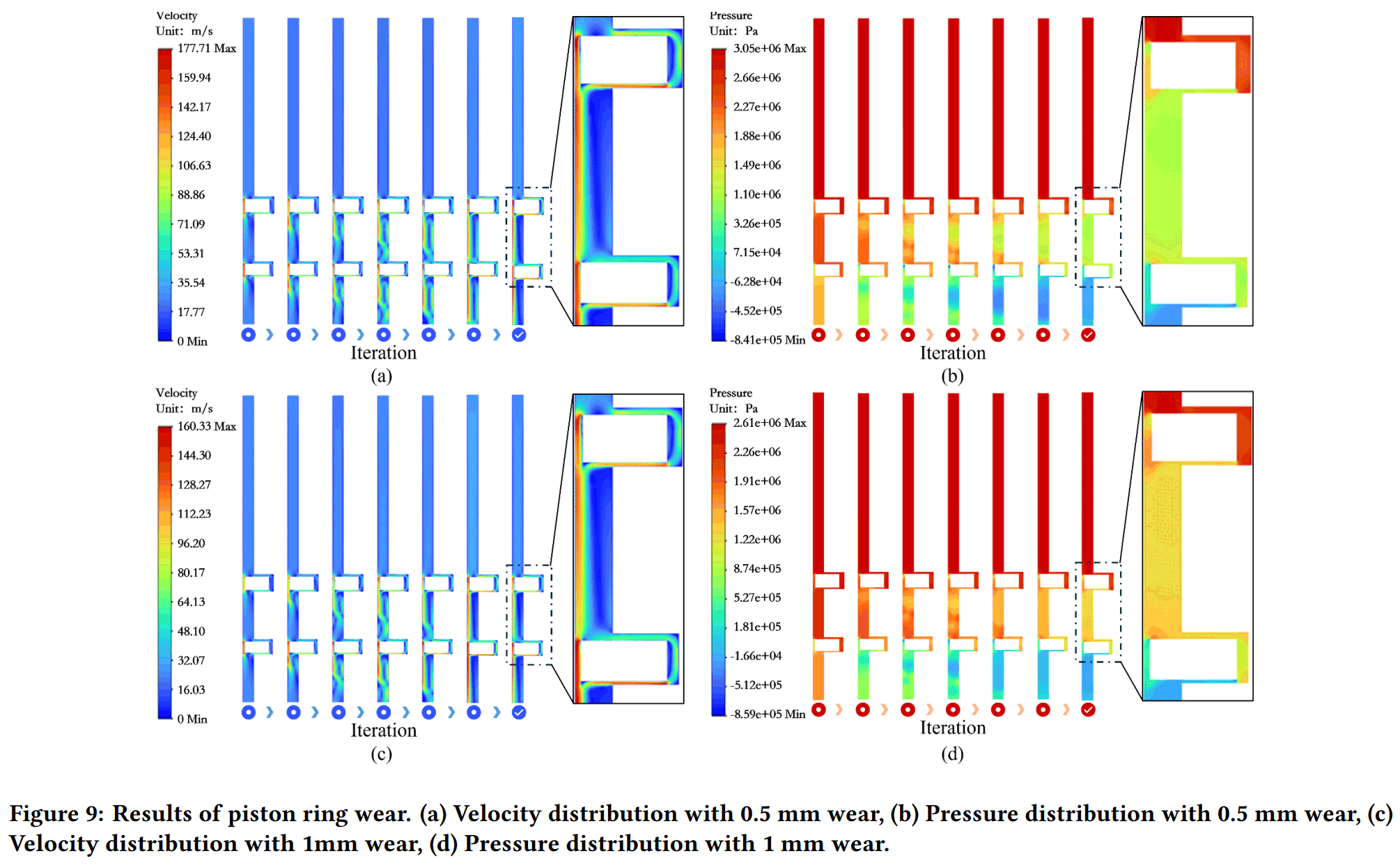

First, by comparing the performance of piston rings in both unworn and worn states, the study investigates the evolution of micro-deformation and the gas leakage flow field, while also exploring the nonlinear characteristics of the fluid dynamics. Simulation results indicate that, even in a normal state, the cross-sectional profile of the piston ring undergoes significant elastic deformation at the moment of maximum combustion pressure. When wear occurs due to lubrication failure, the widening of the wear gap compromises sealing performance; however, the simulation reveals that local gas leakage velocity and pressure exhibit a downward trend, with the rate of decline gradually decelerating. These findings are visually demonstrated through visualized velocity and pressure contours, providing a new perspective for understanding wear-induced leakage mechanisms.

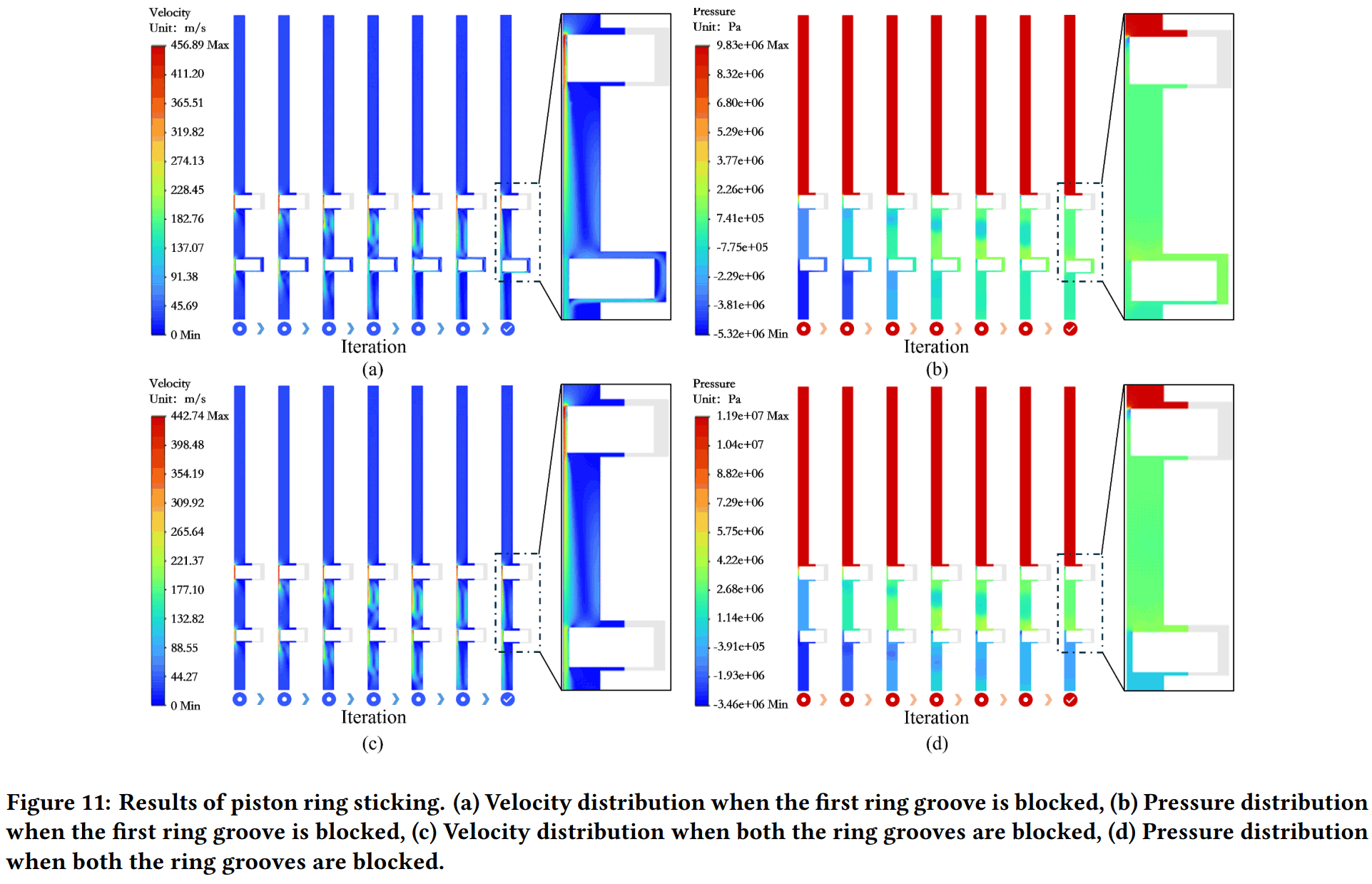

Furthermore, the study identifies piston ring sticking as a potential primary cause of abnormal local pressure elevation within the cylinder, with a destructive potential far exceeding that of wear. When high-temperature carbon deposits restrict the piston ring within the groove, preventing free movement, the gas flow path becomes obstructed, causing a sharp surge in inter-ring pressure. Simulation data shows that the maximum gas pressure under sticking conditions surges from a baseline of 5.27 MPa to 11.92 MPa. Such drastic pressure fluctuations and increased pressure drops are critical factors contributing to cylinder liner failure. This research visualizes the in-cylinder flow field, providing preliminary theoretical data to support the fault diagnosis of marine diesel engines.

References:

Congcong Luo, Minghang Zhao, Song Fu, Yan Zhang, Yan Han, Qingqing Huang, Zhiquan Cui. Numerical simulation of piston rings in marine diesel engines considering thermal-fluid-structure factors: From normal to gas leakage conditions. In 2024 International Conference on Industrial Automation and Robotics (IAR 2024), October 18–20, 2024, Singapore, Singapore. ACM, New York, NY, USA, 7 pages.

https://dl.acm.org/doi/10.1145/3707402.3707412

BibTeX:

@inproceedings{Luo2024,

author = {Congcong Luo and Minghang Zhao and Song Fu and Yan Zhang and Yan Han and Qingqing Huang and Zhiquan Cui},

title = {Numerical simulation of piston rings in marine diesel engines considering thermal-fluid-structure factors: From normal to gas leakage conditions},

booktitle = {2024 International Conference on Industrial Automation and Robotics (IAR)},

year = {2024},

pages = {51--57},

publisher = {ACM},

doi = {10.1145/3707402.3707412}

}