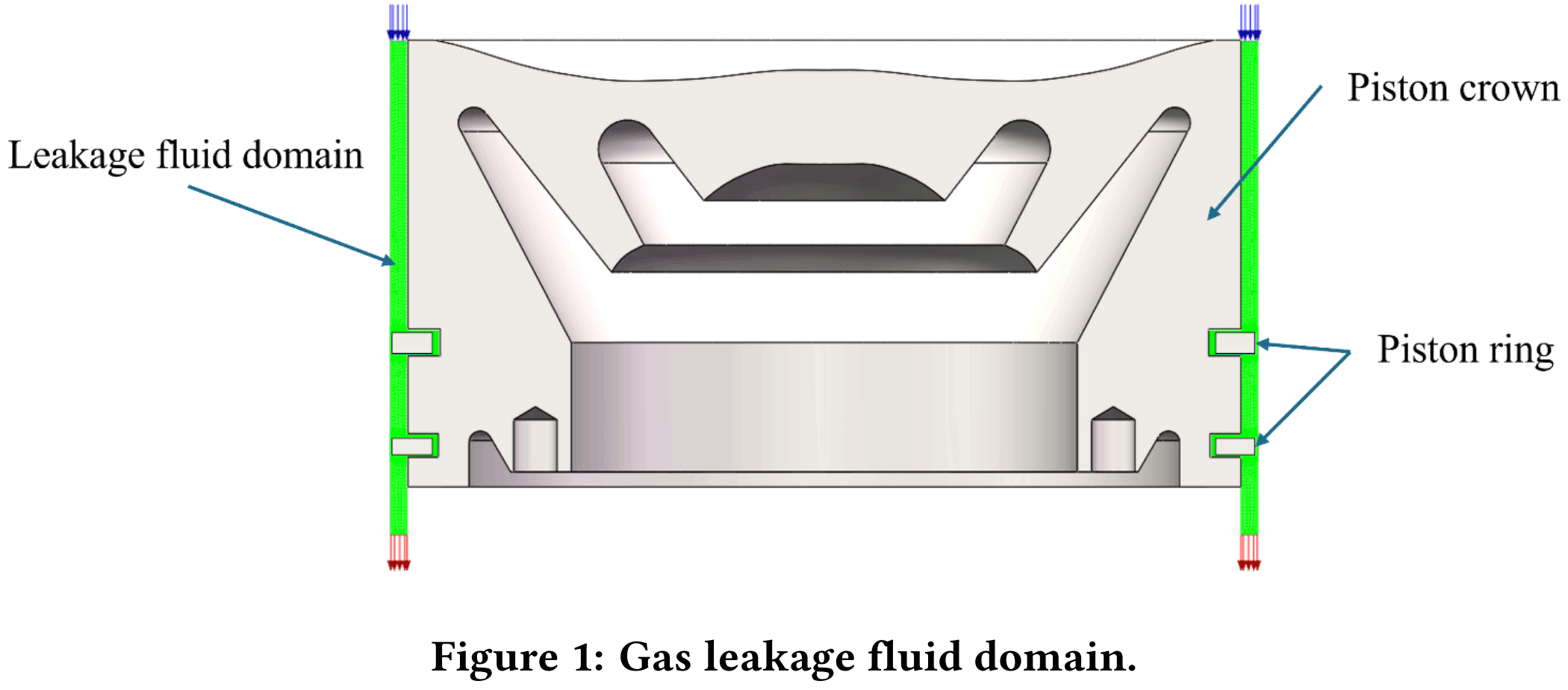

针对大型船舶柴油机难以开展破坏性实验的局限性,数值模拟已成为揭示活塞环故障机理及弥补实验数据缺失的关键手段。该论文针对活塞环、活塞及气缸壁系统,建立了一个融合二维流体域与三维活塞环结构的耦合模型,在考虑热-流-固多物理场因素的条件下进行了求解。相较于单一的流体分析,该模型将气体粘度随温度和压力的变化规律、k-𝜖湍流模型以及受力后的活塞环结构变形纳入统一计算框架,以模拟气缸内复杂的物理环境。

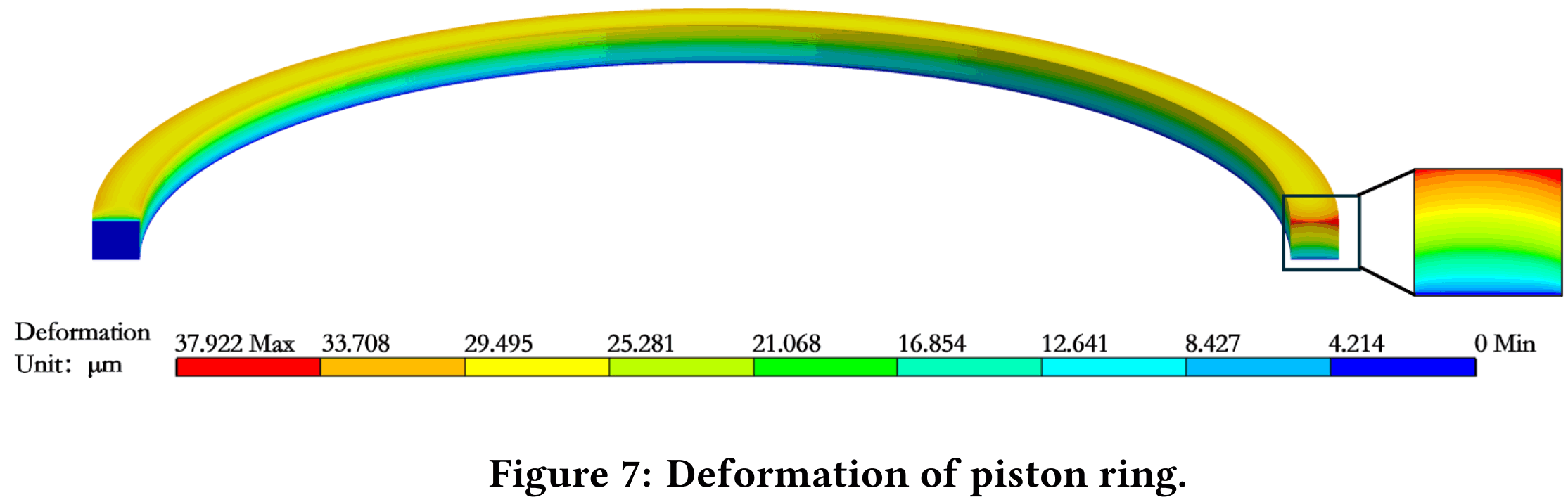

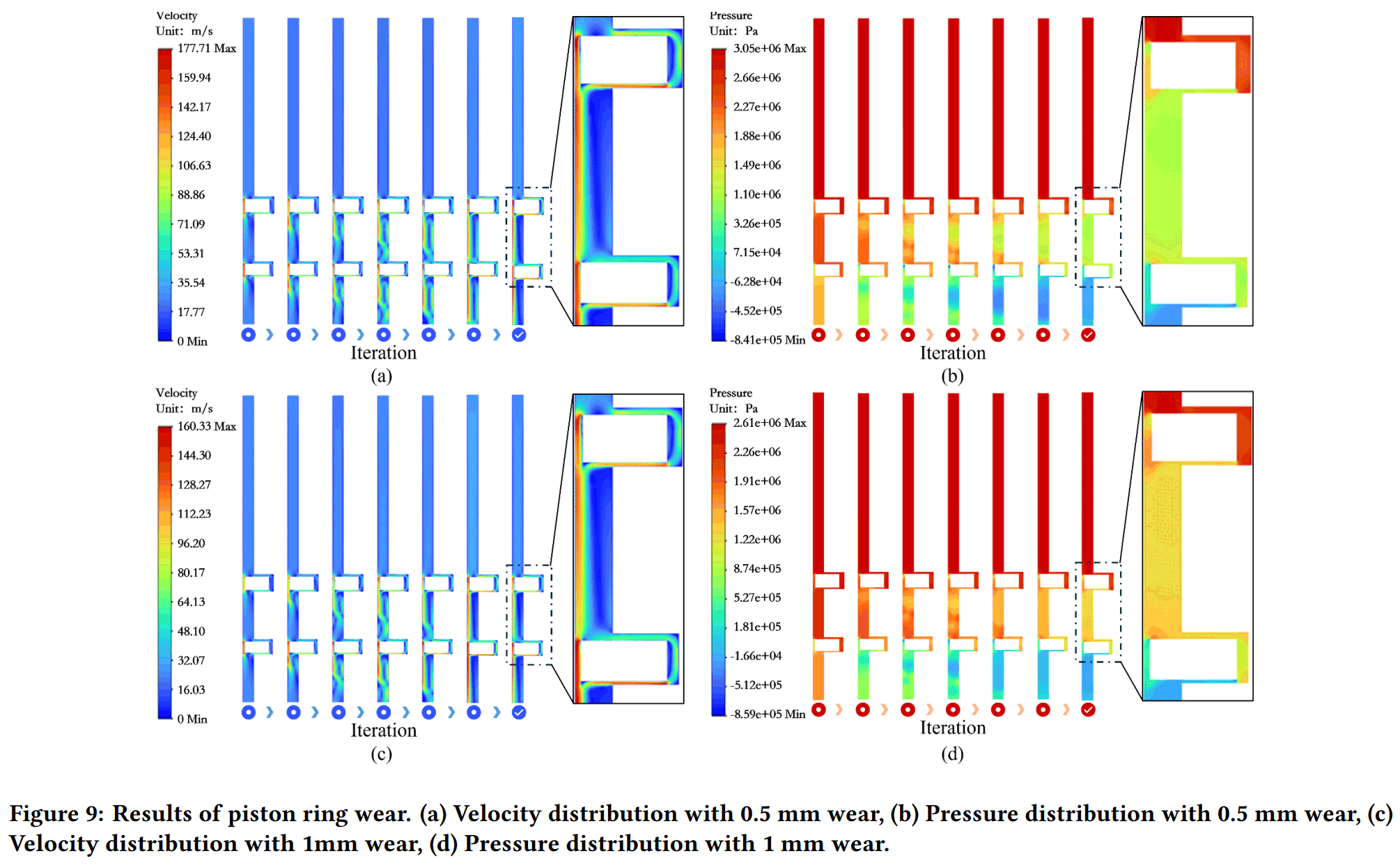

首先,通过对比活塞环在未磨损与磨损状态下的工作表现,研究了其微观变形与燃气泄漏流场的演变规律,并探讨了流体动力学方面的非线性特征。仿真结果表明,在正常状态下的最大爆发压力时刻,活塞环的截面轮廓仍会产生较为显著的弹性变形;当活塞环因润滑失效发生磨损时,随着磨损间隙的增加,尽管泄漏通道变宽导致密封性能下降,但仿真显示的局部气体泄漏速度和压力呈现出下降趋势,且下降速率逐渐减缓。这一发现通过可视化的速度与压力云图进行了直观展示,为理解磨损引致的泄漏机理提供了新视角。

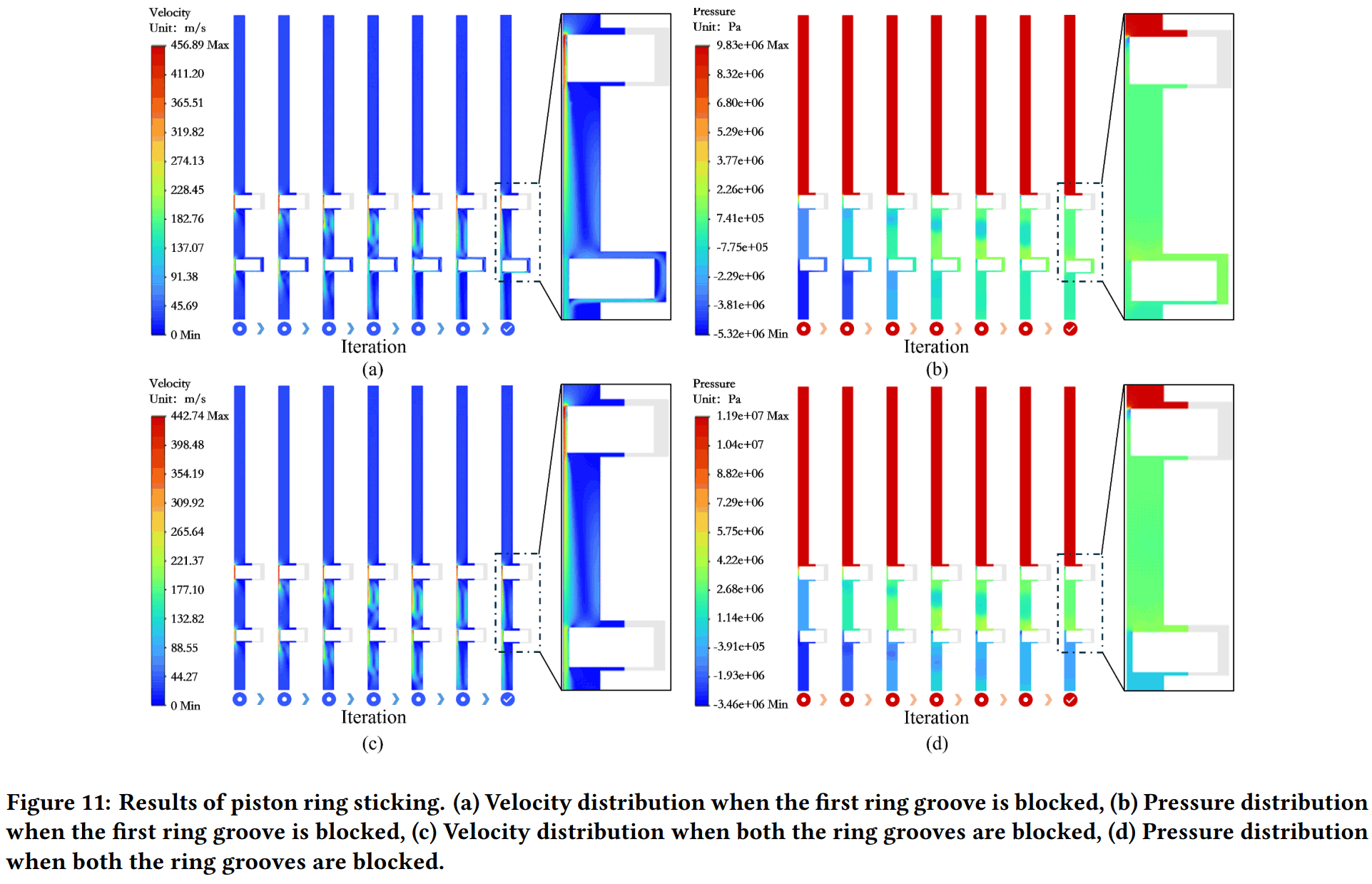

然后,活塞环黏着可能是导致缸内局部压力异常升高的主要原因,其破坏性远超磨损。当高温积碳导致活塞环在环槽内受阻无法自由移动时,气体流动通道被阻塞,致使环间压力急剧上升。仿真数据显示,黏着状态下的气体最大压力从正常值的5.27 MPa激增至11.92 MPa,这种剧烈的压力波动和压降增加是诱发气缸套失效的重要因素。该研究开展了缸内流场的可视化,为船用柴油机的故障诊断提供了初步的理论数据支撑。

参考文献:

Congcong Luo, Minghang Zhao, Song Fu, Yan Zhang, Yan Han, Qingqing Huang, Zhiquan Cui. Numerical simulation of piston rings in marine diesel engines considering thermal-fluid-structure factors: From normal to gas leakage conditions. In 2024 International Conference on Industrial Automation and Robotics (IAR 2024), October 18–20, 2024, Singapore, Singapore. ACM, New York, NY, USA, 7 pages.

https://dl.acm.org/doi/10.1145/3707402.3707412

BibTeX:

@inproceedings{Luo2024,

author = {Congcong Luo and Minghang Zhao and Song Fu and Yan Zhang and Yan Han and Qingqing Huang and Zhiquan Cui},

title = {Numerical simulation of piston rings in marine diesel engines considering thermal-fluid-structure factors: From normal to gas leakage conditions},

booktitle = {2024 International Conference on Industrial Automation and Robotics (IAR)},

year = {2024},

pages = {51--57},

publisher = {ACM},

doi = {10.1145/3707402.3707412}

}